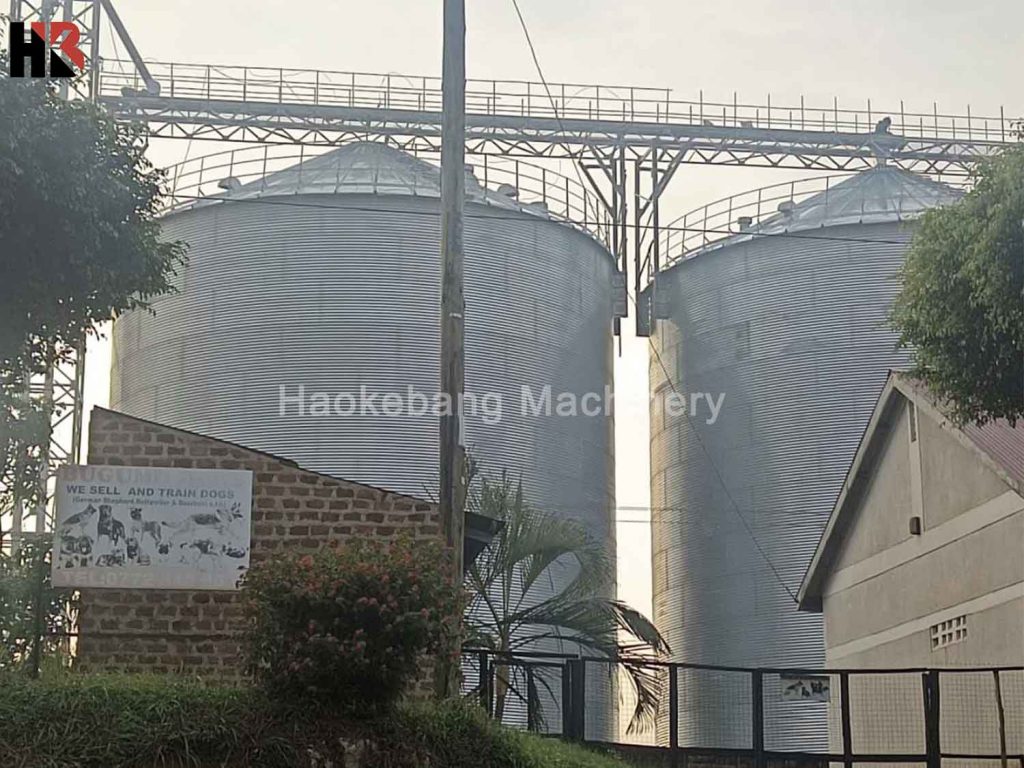

The exterior design of grain silo not only affects storage efficiency but also directly relates to equipment lifespan and operating costs. As a professional grain silo manufacturer, HKB will analyze the design essentials in this article to help us choose more scientific and reliable silo solutions.

Demand Matching: Adjust silo slope and opening design based on grain type (e.g., wheat, corn, rice) to prevent accumulation and mold.

Visual Optimization: HKB uses streamlined silo roofs and modular assembly techniques to combine industrial aesthetics with construction convenience.

Wind and Earthquake Resistance: For coastal and high-altitude areas, HKB silos use circular reinforcement ribs and foundation anchoring technology to enhance stability.

Climate Protection: The silo exterior wall features a double-layer insulation coating (reducing temperature by 5-8°C) to minimize grain loss due to high temperatures.

Galvanized Steel Sheets: Thickness of 0.8-1.2mm, with corrosion resistance tripled compared to traditional carbon steel.

Patented Coating Technology: HKB's coating can withstand acid rain, extending service life to over 20 years.

Optimized Cone Bottom Angle: Using fluid dynamics simulation, HKB sets the outlet inclination angle at 45°-50°, reducing residual rate by up to 90%.

Modular Assembly: Supports rapid assembly of silos with diameters ranging from 6 to 30 meters, reducing transportation and installation costs.

Solar Roof Integration: Optional photovoltaic power supply system for lighting and temperature control devices.

Rainwater Recycling Device: design of roof diversion groove, saving up to 200 tons of water annually (example: 15-meter diameter silo).

Corporate Logo Integration: Supports printing of corporate logos and safety warning slogans on the silo exterior wall.

Color Scheme Customization: Over 200 RAL color options available to match the overall visual planning of the plant area.

Weld Seam Smoothness: No burrs or incomplete welding (HKB uses laser automatic welding technology).

Coating Uniformity: Detected with a magnetic thickness gauge, HKB's coating thickness error is ≤0.05mm.

Sealing Test: After pressurizing the silo to 500Pa, a leakage rate of <0.5%/hour is considered qualified.

Parameter Industry Standard HKB Typical Value

Wind Pressure Resistance ≥1.5kPa 2.2kPa

Installation Period 60 days/1000 tons 35 days/1000 tons.