Coffee bean silo, as a specialized storage solution for coffee beans, are designed and structured to meet the storage needs of this unique commodity.

To preserve the freshness and flavor of coffee beans, coffee bean silos incorporate innovative measures in their design to ensure the quality of the beans remains intact during storage.

Design Considerations:

The design of coffee bean silo takes into account the physical and chemical properties of coffee beans. Sensitive to temperature, humidity, light, and oxygen, silos use insulated, moisture-proof, light-proof, and well-sealed materials to shield the beans from external influences. Additionally, the internal air circulation system regulates humidity and temperature within the silo, further protecting the beans' quality.

Mechanized Operations:

Compared to traditional storage methods, coffee bean silo adopt advanced mechanized operation technology, significantly improving storage efficiency. Equipped with automated loading and unloading systems, silos facilitate quick, safe coffee bean transfer, reducing manual labor and error rates. This mechanization not only boosts work efficiency but also lowers potential risks to bean quality during operations.

Hopper Bottom Design:

Specialized designs at the bottom of coffee bean silo ensure smooth material discharge. By optimizing the material flow path, this design minimizes residue during discharge, enhancing cleanliness. This efficient discharge design is suitable not only for coffee beans but also for other materials with poor flowability.

Multifunctionality:

Though primarily designed for coffee bean storage, the versatility of coffee bean silos makes them suitable for industries like seeds, flour, aquaculture, and chemicals. Particularly for applications with moderate storage needs and frequent material turnover, their flexible and efficient operation allows rapid adaptation to various storage requirements.

Coffee bean silo consist of three parts: the roof, the body, and the base. The body is the main part of the silo. Each component is carefully designed and manufactured to ensure the silo maintains the quality of coffee beans without damage during long-term storage.

Silo Roof:

The roof beams of coffee bean silos are made from C-shaped steel, widely used for its lightweight and high-strength properties. Connected to the silo's top ring and supports, they form a robust frame structure. Horizontal connections with angle steel enhance the roof's overall stability. This design ensures the roof withstands natural conditions like rain, snow, and extends the silo's lifespan.

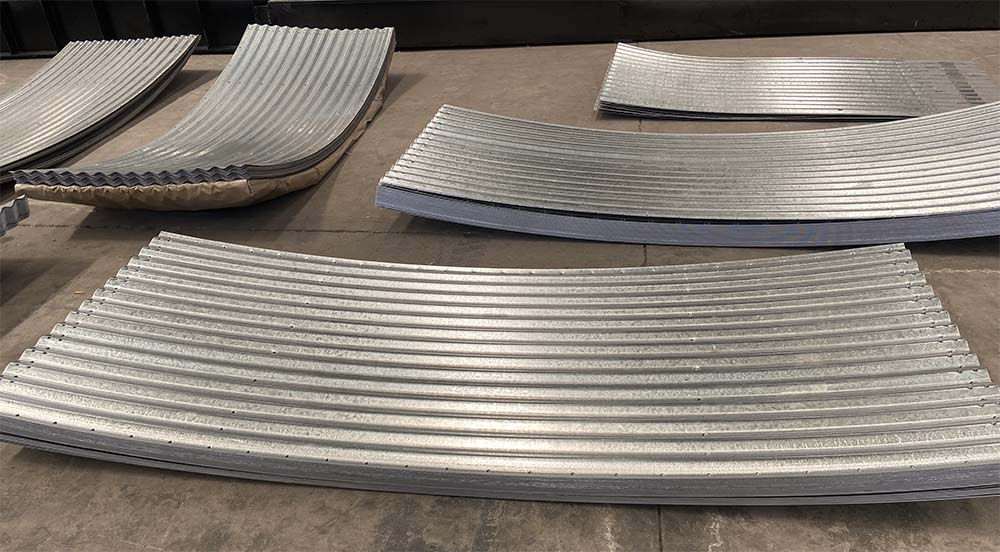

Silo Body:

The silo body, the core structure for storing coffee beans, is crafted from high-density galvanized steel sheets. These materials offer excellent corrosion and wear resistance, protecting the beans from environmental harm. The thickness of the cladding increases from top to bottom, adapting to stress changes at different heights and ensuring the silo body's strength at all levels.

Access Ladders and Doors:

For convenient and safe maintenance and inspection, ladder rungs are punched to prevent rotation during climbing, ensuring user safety. Maintenance doors are also designed with safety and convenience in mind, typically located on the silo's side or top for easy access to the interior for necessary upkeep and inspections.

From initial project analysis to the final turnkey completion of your customized silo system, Coban's engineers stand with you for the best matching solutions. Reach out if you need our services!