Peanuts, as an important oil crop and food ingredient, require proper storage processes to maintain quality and enhance economic benefits. Innovations and optimizations in peanut grain silo process not only improve storage efficiency but also reduce losses and extend shelf life.

Innovation is a key factor driving the development of peanut grain silo process. Here is a detailed analysis of technological innovation:

Intelligent Management System

The process integrates an intelligent management system with sensors, monitoring equipment, and data analysis software. This achieves real-time monitoring and automatic adjustment of storage environments. The system precisely controls key parameters like temperature, humidity, and oxygen levels inside the peanut grain silo. This ensures the quality and safety of peanuts during storage. For example, energy-saving silo air conditioning technology boosts the silo's energy efficiency and reduces energy consumption.

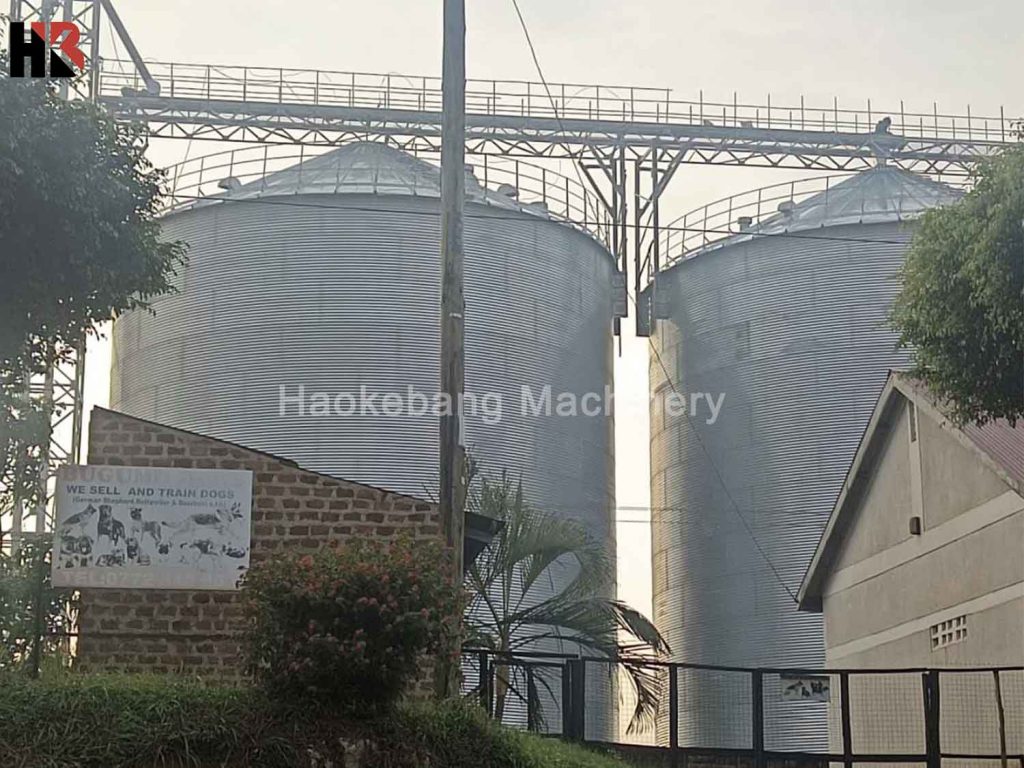

Anti-corrosion and Protection Technologies

To improve the durability and safety of peanut grain silos, advanced anti-corrosion and protection technologies are employed in the process. Applying anti-rust paint or using galvanization processes on the silo surface enhances its corrosion resistance and extends its lifespan. The silo also implements various technical measures, including waterproofing, moisture-proofing, condensation-proofing, fireproofing, pest-proofing, rodent-proofing, bird-proofing, theft-proofing, lightning-proofing, typhoon-proofing, ventilation, airtightness, and insulation.

The market expansion strategy of peanut grain silo process is crucial for business development. Here is a detailed analysis of the strategy:

Market Demand Analysis and Positioning

The development of silo processes is closely related to market demand. With the increase in peanut planting area and yield, as well as the widespread application of peanuts in food processing and oil production, the demand for peanut storage is also growing.

Cooperation and Alliance

Silo process enterprises establish cooperative relationships with other companies, research institutions, etc., to achieve resource sharing and complementary advantages. This cooperation and alliance not only help improve the enterprises' technical level and innovation capabilities but also expand market channels and enhance market competitiveness.

Environmental protection and energy saving are important development directions for peanut grain silo process, aligning with the sustainable development concept of modern industry. Here is a detailed analysis of environmental protection and energy saving:

Green Storage Technology

Green storage technology is an essential part of silo processes. By employing advanced airtight materials, high-performance external insulation materials, and environmentally friendly building materials, the silo's insulation and airtight performance are enhanced. Additionally, green storage technologies and processes, such as natural ventilation and low-temperature storage, are implemented. This reduces grain moisture loss and dry matter consumption, achieving optimal storage and preservation.

Energy-saving Measures

In the design and operation of silo processes, emphasis is placed on energy saving and consumption reduction.For instance, the silo air conditioning system employs high-efficiency energy-saving equipment and intelligent control strategies. This enhances system efficiency and operational effectiveness. Furthermore, the silo building's roof can be designed to harness regional solar energy resources. Incorporating photovoltaic power generation facilities or reserving installation conditions achieves energy conservation and utilization.