Grain drying tower is mainly used for large amount drying of corn and rice.

Grain dryer tower is an indispensable drying equipment in large-scale grain storage project. The huge drying capacity can meet the requirements of large-scale grain storage projects and maintain the efficient operation of the entire grain storage project.

It has the characteristics of large processing capacity, high cost performance and direct storage of grain after drying.

– The precipitation range is large, and the maximum precipitation range of a grain dryer tower can reach 25%.

– Mechanized continuous operation of grain dryer tower, stable performance, convenient operation, saving civil construction investment.

– It has strong adaptability and can take into account the drying of many varieties of grains.

– The corn dryer can use waste heat to recycle to reduce energy consumption.

– The grain is dried thoroughly and evenly, with sufficient slow down and thorough cooling, and the dried grain can be put into storage directly.

– Applying a number of energy-saving technologies, the drying energy consumption is low and drying costs are saved. After baking, the grain quality is good and pollution-free.

– A variety of heat sources can be used for heating: natural gas, steam, coal, fuel oil, biomass particles, etc.

Grain dryer tower is mainly used for large amount drying of corn and rice.

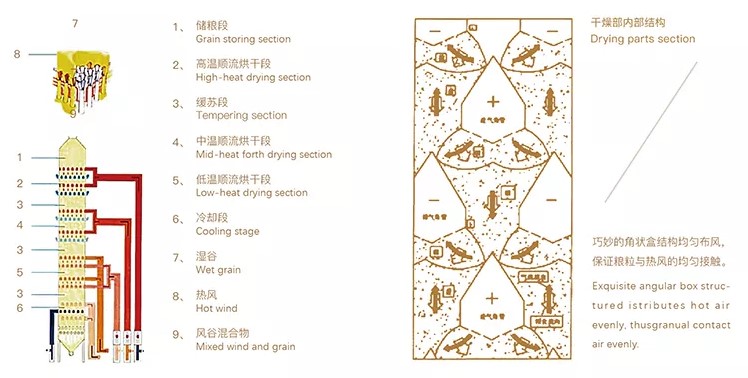

This model adopts the downstream drying process and is a downstream dryer. The downstream dryer uses hot air as the heating medium to dry the grain.

Its interior is mainly composed of air intake ventilation joints and angular ventilation boxes. The corner box is filled with grain, and the grain flows from top to bottom.

The hot air enters through the air intake and ventilation section and passes through the grain layer in the downward direction. The exhaust gas is discharged through the exhaust corner box. The hot air flows in the same direction as the grain flow, which is called mixed flow.

When the hot air passes through the grain layer, it transfers heat and moisture with the grain: the hot air transfers heat to the grain to increase its temperature. When the grain is heated, the moisture evaporates into the air and becomes exhaust gas.

The dried hot grain flows down to the slow-supply section, and after the slow-supply section, the temperature and moisture of the inner and outer layers of the grains tend to be balanced to achieve uniform precipitation.

After the grain has slowed down, it enters the cooling section. After cooling, the grain is cooled to the storage temperature, and then discharged from the grain discharge section.

The Grain dryer machine is suitable for efficiently drying all cereals, grains, beans, and seeds of all crops such as corn, wheat, rice, soybean, sorghum, rapeseed, cashew, barley, etc. It is suitable for all kinds of farms.

| Model | HKB100 | HKB150 | HKB200 | HKB300 | HKB400 | HKB500 | HKB600 |

| Capacity (T/D) | 100 | 150 | 200 | 300 | 400 | 500 | 600 |

| Moisture Expected Lowed Down (%) | 3~5 | ||||||

| Heated Media | Cleaning Air | ||||||

| Heated Air Tempereture

(℃) |

<65 | ||||||

| Maximum Heating Temperature of Grain (℃) | 35 | ||||||

| Drying Evenness (%) | >98 | ||||||

| Unit Heat Consumption

(kj/kgH2O) |

5450~6700 | ||||||

| Coal Consumption

(Standard) (kg/h) |

110~180 | 160~260 | 230~350 | 340~520 | 450~680 | 560~850 | 700~1000 |

| Installation Capacity | According to the environment, conditions, expected moisture lowed down and configuration. | ||||||

| Dryer Size(M) | 4×3 | 4×3 | 5.5×3.2 | 5.5×4 | 5.5×4 | 6.2×6 | 6.2×6 |

| Dryer Height(M) | 9~12 | 12~15 | 14~17 | 16~18.5 | 18~20 | 16~19 | 18~21 |

Henan Haokebang Machinery Equipment Co., Ltd. specializes in the production of 100-10,000 ton hopper bottom and flat bottom corrugated galvanized steel silos. According to various factors such as site, weather, and geology, we provide professional silo design, equipped with elevators, unloading pits, pre-cleaner, conveyors, sweeping auger and other accessories to meet the diverse needs of customers.