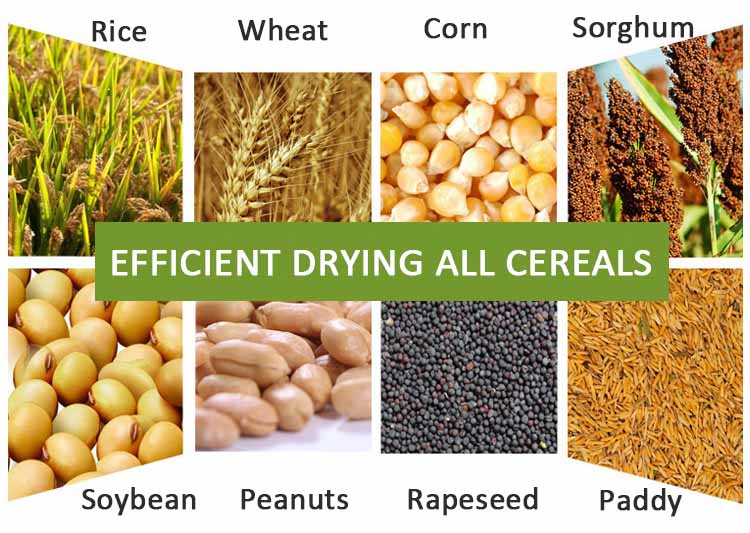

HKB grain bin is widely used for grains storage such as wheat, corn, soybean, paddy, rice, soybean meal, barley, malt, sunflower seeds, rapeseeds, peanuts, flour, and other powder materials, oat, special grain, and seeds, etc.

Grain bin actively function as large-capacity containers or buildings specifically built for the purpose of storing grains like wheat, corn, soybeans, and other agricultural commodities. They are primarily constructed with steel or alternative materials, which actively contribute to safeguarding the stored grains against the detrimental effects of moisture, pest infestation, and fluctuating temperatures.

Grain bins, as agricultural storage facilities, possess a variety of characteristics that make them play an essential role in modern agricultural production.

Grain bin actively utilize sturdy and durable materials such as steel, concrete, or plastic for construction, to withstand the weight of the grain and resist external environmental erosion.

Grain bin actively present a variety of designs and shapes, such as circular, square, or rectangular, adapting to different storage needs and spatial conditions.

Grain bin actively offer customized sizes to ensure the ability to accommodate abundant grain reserves, such as corn, soybeans, and other feed grains.

Most grain bin actively remain as fixed structures, providing a long-term and stable storage environment for grain once constructed at a particular location.

Grain bin are no longer just static storage units but actively incorporate various high-tech features, such as temperature control, humidity monitoring, and automatic ventilation systems, to ensure the quality of the grain is maintained during storage.

Although the initial investment for grain bin may be high, with technological advancements and design improvements, grain bins actively provide substantial returns, reducing grain loss and enhancing the economic benefits of agricultural production through efficient storage and management.

Farmers actively consider a variety of factors when purchasing new grain bin, including capacity, cost, durability, and technological features, to ensure the applicability and cost-effectiveness of the chosen grain bin.

In summary, grain bin actively serve as an indispensable part of modern agriculture, supporting the continuous development of agricultural production by providing safe, efficient, and reliable grain storage solutions. As technology continues to advance, grain bin will also continue to evolve to meet the higher demands of future agriculture.

The structure and components of a Grain Bin, which is designed for the storage of grain or other bulk materials, include several key elements that collectively ensure the safe storage and efficient management of materials:

The foundation serves as the support base for the entire Grain Bin structure, bearing the weight of the silo and its contents. It must be robust enough to handle the load and is designed considering geological conditions, load distribution, and potential ground settlement.

The silo wall is the main body of the Grain Bin, directly in contact with the stored material. It must possess adequate strength and rigidity to withstand the lateral pressure from the material. Silo walls can be constructed from various materials such as reinforced concrete, steel, or masonry.

The roof covers the top of the silo, protecting the contents from external environmental factors like rain, snow, and sunlight. The roof is typically designed to withstand certain external loads.

The floor is the base part of the silo, supporting the entire structure. Floor design considerations include the method of material discharge and the convenience of mechanical operations.

Located between the foundation and the silo wall, the support structure ensures the stability of the silo. This may include columns, beams, or other supporting elements.

These systems allow materials to enter and exit the silo. Inlet systems often include conveyor belts, screw conveyors, or other mechanical equipment. Outlet systems are designed to ensure a uniform and continuous flow of materials.

A ventilation system is crucial for maintaining the internal environmental conditions of the silo, preventing spoilage and mold growth of the materials. It may include natural or mechanical ventilation equipment.

Modern silos may be equipped with monitoring and control systems that provide real-time surveillance of key parameters such as temperature, humidity, and material levels within the silo, allowing for adjustments as needed.

To ensure the safety of operators and equipment, silos may incorporate various safety features, such as fall arrest systems, emergency stop buttons, and warning signs.

These components actively work together to form the structure of a silo, ensuring effective storage and management of grain and other bulk materials. The design also takes into account ease of operation, simplicity of maintenance, and long-term durability.

Coban Soybean Meal Silo is widely used for grains storage such as wheat, corn, soybean, paddy, rice, soybean meal, barley, malt, sunflower seeds, rapeseeds, peanuts, flour, and other powder materials, oat, special grain, and seeds, etc.

Scientifically speaking, silo capacity should be measured in volume (m3). Even in the same grain Silo, the storage tons will be different for different grains with different densities. The following table is calculated based on a Silo density of 0.75kg/m3, and surely HKB customizes Silo systems unique for you.

| Most Popular Hopper Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 50Ton | 100Ton | 150Ton | 200Ton | 300Ton | 500Ton | 1000Ton | 1500Ton |

| Model | TCZK

03605 |

TCZK

04507 |

TCZK

05507 |

TCZK

06406 |

TCZK

07307 |

TCZK

07313 |

TCZK

11010 |

TCZK

12811 |

| Diameter(m) | 3.667 | 4.584 | 5.500 | 6.417 | 7.334 | 7.334 | 11.000 | 12.834 |

| Total Height(m) | 9.56 | 12.53 | 13.25 | 12.85 | 14.70 | 21.42 | 20.95 | 23.51 |

| Volume(m³)

Density:0.75ton/m³ |

69 | 150 | 222 | 273 | 415 | 699 | 1346 | 2039 |

| Most Popular Flat Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 1000Ton | 1500Ton | 2000Ton | 2500Ton | 3000Ton | 5000Ton | 8000Ton | 10000Ton |

| Model | TCK

10014 |

TCK

11915 |

TCK

13715 |

TCK

15514 |

TCK

15518 |

TCK

18321 |

TCK

24718 |

TCK

25621 |

| Diameter(m) | 10.084 | 11.918 | 13.750 | 15.584 | 15.584 | 18.334 | 24.751 | 25.668 |

| Total Height(m) | 18.69 | 20.34 | 20.87 | 20.30 | 24.78 | 28.60 | 26.99 | 30.60 |

| Volume(m³)

Density: 0.75ton/m³ |

1335 | 2009 | 2701 | 2467 | 4145 | 6693 | 10879 | 13484 |