HKB Grain Silo is widely used for grains storage such as wheat, corn, soybean, paddy, rice, soybean meal, barley, malt, sunflower seeds, rapeseeds, peanuts, flour, and other powder materials, oat, special grain, and seeds, etc.

2000 tons of grain storage usually uses flat bottom silo.

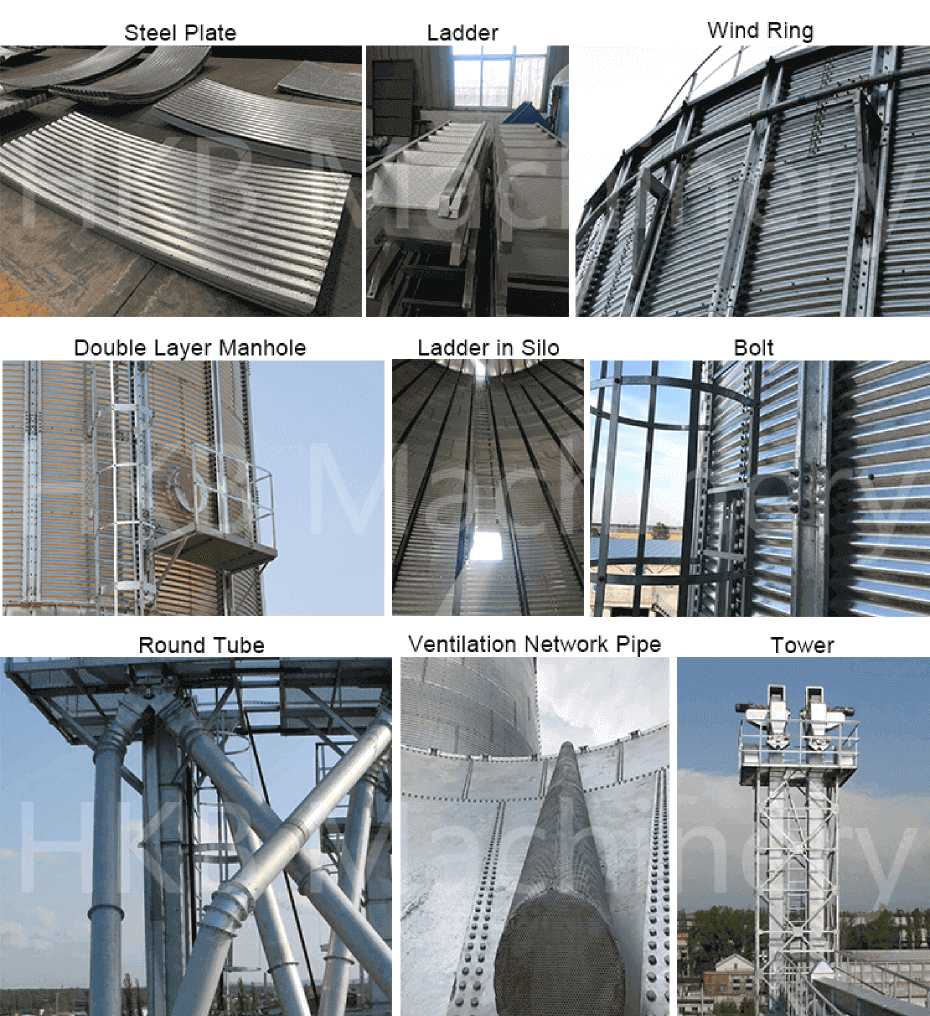

HKB grain silos are made of high quality 275g/m2, 300g/m2, 350g/m2 hot-dip galvanized steel plates which are rolled into corrugation and made into standard connecting holes. The vertical friction is support by the steel silo stiffeners which are evenly vertically applied in the silos. The connecting screw bolts are served with round galvanized steel washers, the connecting holes are served with age-resistant and water-proof daub belts that are for aviation special purpose.These plates and stiffeners are connected by high-strength screw bolts to keep the flat silo strong and durable. The hopper bottom silos are equipped with flat repairing doors, outside ladder and ladder guard rings.

1. 2000 ton grain silo Assembly, easy to ship and save freight.

2.Hot-dip galvanized plates (275g/m2-600g/m2), very WATERPROOF &RUST-PROOF.

3.Flat bottom has large capacity from 1500T-20000T.

4.Silos can store grain safely and save labor cost and space.

How do we assure the silo solidity?

Scientifically speaking, the silo capacity should be measured with volume (m3). Even in the same silo, the storage tons will be different for different grains with different densities. The following table is calculated based on a grain density of 0.75kg/m3, and surely HKB customizes silo systems unique for you.

| 2000 Ton Flat Bottom Grain Silo Technical Parameter | |||||

| Model | Layer | V(m3) | C(t) | Diameter(m) | High(m) |

| TCK13715 | 15 | 2701 | 2026 | 13.750 | 20.87 |

| TCK13716 | 16 | 2868 | 2151 | 13.750 | 21.99 |

| TCK13717 | 17 | 3034 | 2275 | 13.750 | 23.11 |

| TCK13718 | 18 | 3200 | 2400 | 13.750 | 24.23 |

| TCK14613 | 13 | 2710 | 2032 | 14.668 | 18.89 |

| TCK14614 | 14 | 2899 | 2174 | 14.668 | 20.01 |

| TCK14615 | 15 | 3089 | 2316 | 14.668 | 21.13 |

| TCK14616 | 16 | 3278 | 2458 | 14.668 | 22.25 |

| TCK14617 | 17 | 3467 | 2600 | 14.668 | 23.37 |

| TCK14618 | 18 | 3656 | 2742 | 14.668 | 24.49 |

| TCK14619 | 19 | 3846 | 2884 | 14.668 | 25.61 |

| TCK15513 | 13 | 3076 | 2307 | 15.584 | 19.18 |

| TCK15514 | 14 | 3290 | 2467 | 15.584 | 20.30 |

| TCK15515 | 15 | 3504 | 2628 | 15.584 | 21.42 |

| TCK15516 | 16 | 3717 | 2788 | 15.584 | 22.54 |

| TCK15517 | 17 | 3931 | 2948 | 15.584 | 23.66 |

| TCK16514 | 14 | 3707 | 2780 | 16.500 | 20.26 |

| TCK16515 | 15 | 3947 | 2960 | 16.500 | 21.38 |

Henan Haokebang Machinery Equipment Co., Ltd. specializes in the production of 100-10,000 ton hopper bottom and flat bottom corrugated galvanized steel silos. According to various factors such as site, weather, and geology, we provide professional silo design, equipped with elevators, unloading pits, pre-cleaner, conveyors, sweeping auger and other accessories to meet the diverse needs of customers.