HKB Grain Silo is widely used for grains storage such as wheat, corn, soybean, paddy, rice, soybean meal, barley, malt, sunflower seeds, rapeseeds, peanuts, flour, and other powder materials, oat, special grain, and seeds, etc.

As the name implies, 500 ton grain silo warehouse is a warehouse for storing grain. The selection of grain silo should be conducive to food security storage, be advanced to a certain extent, be conducive to the realization of mechanization,and be suitable for the implementation of advanced grain storage technology.

For 500 tons of grain storage, we usually recommend hopper bottom silo. Hopper bottom steel silos store materials out of the silos with good self-cleaning effect and no residue. The warehouse is suitable for seed, flour, aquaculture, chemical and other industries with moderate reserves and frequent silos. The hopper bottom steel silo support structure of the cone-bottom steel plate warehouse is strong and the cone-bottom strength is high.

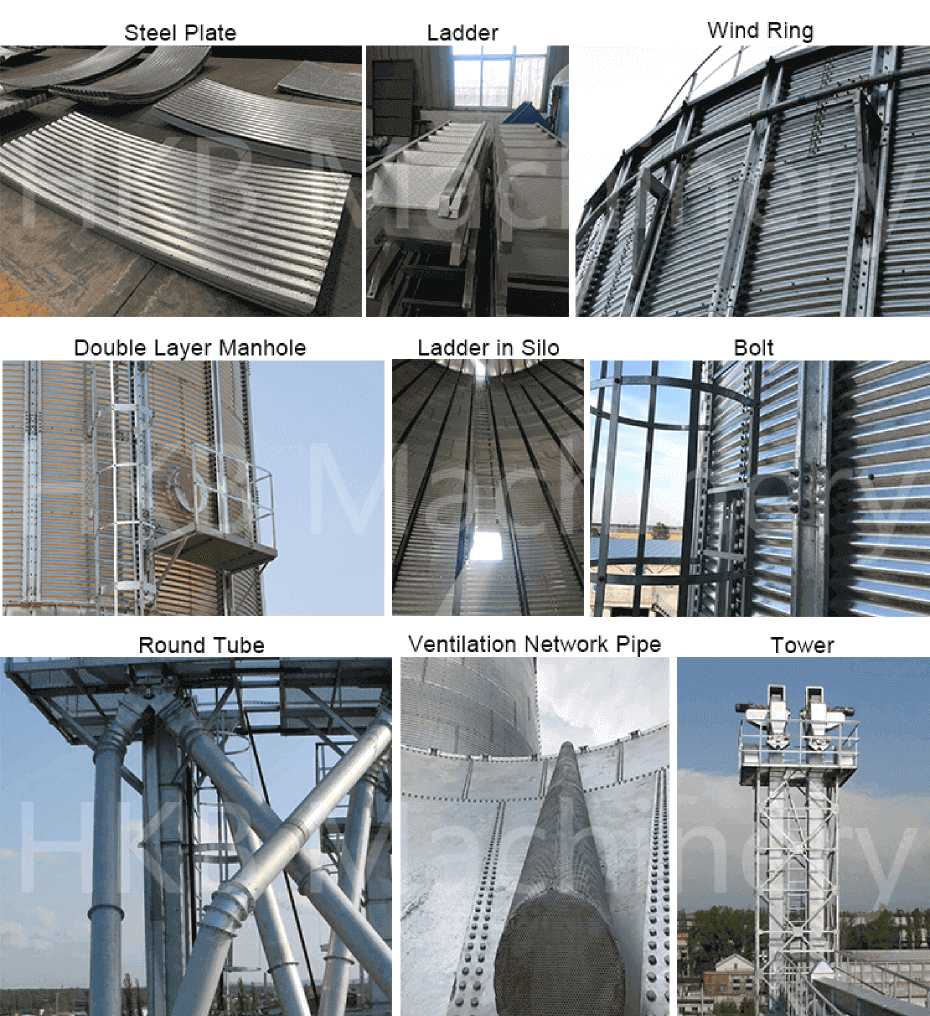

1、500 ton grain silo Assembly, easy to ship and save freight.

2、Hot-dip galvanized plates (275g/m2-600g/m2), very WATERPROOF &RUST-PROOF.

3、Hopper bottom has low cost price.

4、500 ton grain silo can store grain safely and save labor cost and space.

How do we assure the silo solidity?

Scientifically speaking, the silo capacity should be measured with volume (m3). Even in the same silo, the storage tons will be different for different grains with different densities. The following table is calculated based on a grain density of 0.75kg/m3, and surely HKB customizes silo systems unique for you.

| 500 Ton Steel Silo Technical Parameter | |||||

| Project | Layer Number | V(m3) | C(t) | Dia(m) | H(m) |

| TCZK07313 | 13 | 699 | 524 | 7.334 | 21.42 |

| TCZK08210 | 10 | 718 | 538 | 8.250 | 18.87 |

| TCZK08211 | 11 | 778 | 583 | 8.250 | 20.00 |

| TCK08211 | 11 | 704 | 528 | 8.250 | 14.80 |

| TCK08212 | 12 | 764 | 573 | 8.250 | 15.92 |

| TCK09109 | 9 | 728 | 546 | 9.167 | 12.83 |

| TCK10008 | 8 | 798 | 599 | 10.084 | 11.97 |

Henan Haokebang Machinery Equipment Co., Ltd. specializes in the production of 100-10,000 ton hopper bottom and flat bottom corrugated galvanized steel silos. According to various factors such as site, weather, and geology, we provide professional silo design, equipped with elevators, unloading pits, pre-cleaner, conveyors, sweeping auger and other accessories to meet the diverse needs of customers.