Silo feed system is a complete set of automatic feeding system, included a material conveying pipe, silo, auger, drive motor and a material level sensor. Main Feed line is mainly used to deliver feed from silo to the hopper in the poultry house. There is one feed sensor at the end of main feed line,which can control the drive motor on and off to realize automatic delivery feed.

1.feed silo Long service life with 5-year warranty.

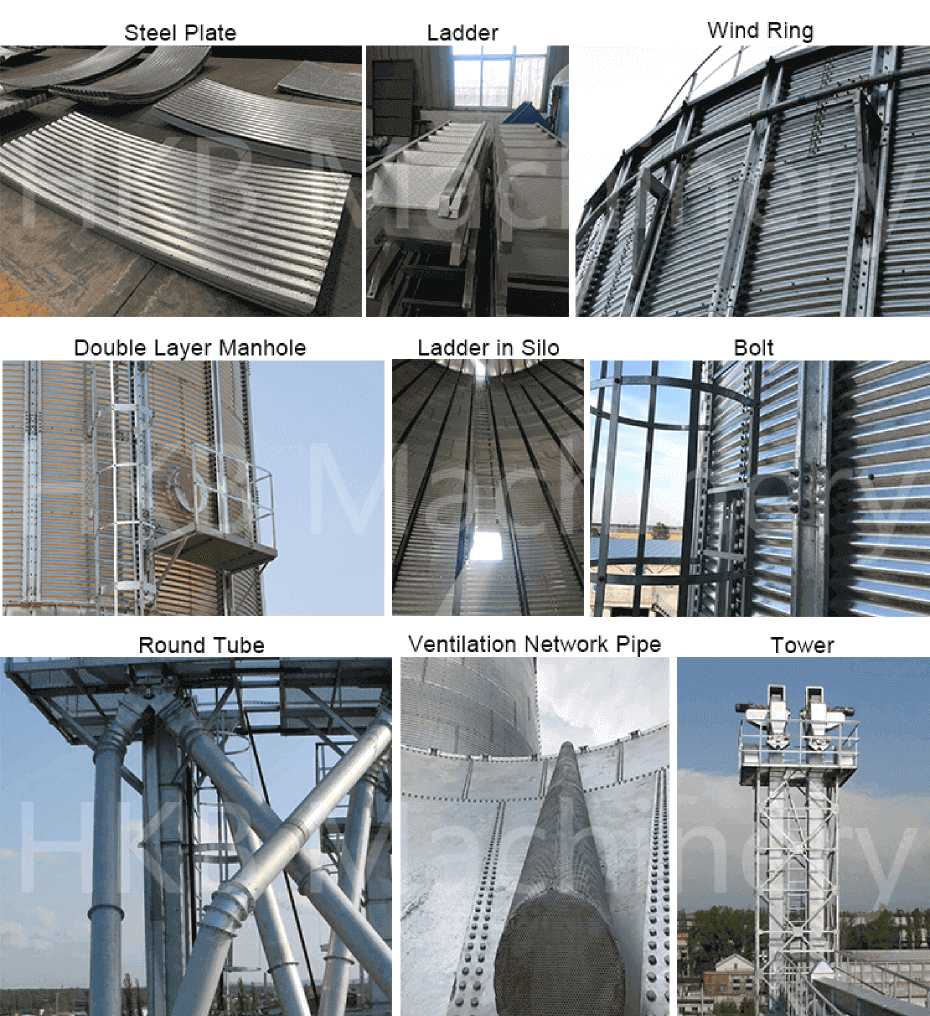

2.Durable construction and reliable support.

3.Superior weather resistant features.

4.Fully accessible bin lid.

5.Remote feed management options.

6.Wide selection of value added accessories.

How do we assure the feed silo solidity?

:Hopper slopes are available in 60° and 67° in either a 16” or 22” hopper opening. Rounded corners and down-turned sealing edges add safety and promote a weather-tight fit. Rounded, truss-head bolts reduces content bridging. Depending on the tank size, single or dual galvanized X-bracing is used to provide solid support and stability.

Scientifically speaking, the feed silo capacity should be measured with volume (m3). Even in the same silo, the storage tons will be different for different grains with different densities. The following table is calculated based on a grain density of 0.75kg/m3, and surely HKB customizes silo systems unique for you.

| Feed Silo Technical Specifications | |||||

| Project | Layer Number | V(m3) | C(t) | Dia(mm) | H(mm) |

| TCKZ01801 | 1 | 4.9 | 3.7 | 1800 | 3580 |

| TCKZ01802 | 2 | 7.9 | 5.9 | 1800 | 4700 |

| TCKZ01803 | 3 | 10.8 | 8.1 | 1800 | 5820 |

| TCKZ01804 | 4 | 13.8 | 10.3 | 1800 | 6940 |

| TCKZ01805 | 5 | 16.8 | 12.6 | 1800 | 8060 |

| TCKZ02701 | 1 | 13.2 | 10 | 2750 | 4640 |

| TCKZ02702 | 2 | 19.9 | 15 | 2750 | 5760 |

| TCKZ02703 | 3 | 26.5 | 20 | 2750 | 6880 |

| TCKZ02704 | 4 | 33.2 | 25 | 2750 | 8000 |

| TCKZ02705 | 5 | 39.8 | 30 | 2750 | 9120 |

Henan Haokebang Machinery Equipment Co., Ltd. specializes in the production of 100-10,000 ton hopper bottom and flat bottom corrugated galvanized steel silos. According to various factors such as site, weather, and geology, we provide professional silo design, equipped with elevators, unloading pits, pre-cleaner, conveyors, sweeping auger and other accessories to meet the diverse needs of customers.